Compact and very lightweight extensometer for direct strain measurement on sensitive material samples.

Innovative dual-flexure design ensures both robustness and flexibility, enabling seamless cyclic tests in both tension and compression modes.

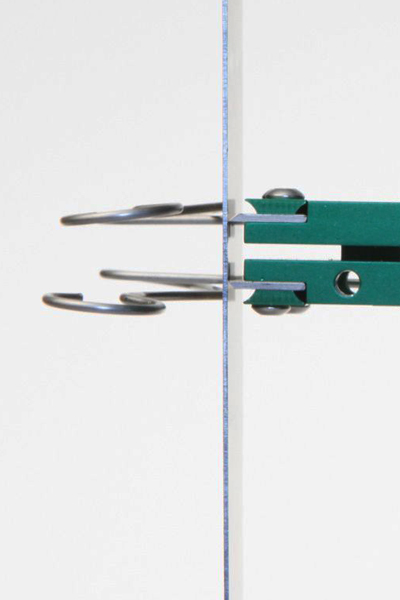

Adaptability is at your fingertips with a range of cutting clamps and diverse retaining springs. These options cater to various flat or round specimens, conforming effortlessly to DIN, ISO, or ASTM standards.

Our FDM-100 series strain sensors offer a comprehensive range of measuring lengths, spanning from 3mm to 50mm, and strain percentages from 1% to 25%.

To ensure the correct setting of the measuring length, an adjustment pin is inserted while the extensometer is mounted on the specimen.

Weighing approximately 8g, our extensometer significantly reduces typical measuring errors associated with contact extensometers. For materials of utmost sensitivity, the additional suspension feature effectively mitigates the impact of transverse forces.

Signals from the strain gauge are amplified in the DAQ box supplied, digitised and sent to the FMT-317 testing machine controller together with the equidistantly recorded force values.

With software version 1.13 and beyond, our controller seamlessly identifies the connected strain sensor, automatically displaying absolute length measurement values.

Within your test's measurement results, you have the choice between accessing absolute values or relative elongation data, tailoring the output to your analytical preferences.

The absolute measured length values serve as a valuable tool for control purposes within your system. Additionally, our limit value monitoring function is in place to prevent strain sensor overload during testing, ensuring reliable and secure operations.

Got a question about this solution?

Get in touch and speak to one of our Technical Sales Engineers now...